Our customers depend on our products to keep their equipment running. Designed and manufactured by Cat we control the quality of the parts you need to keep.

How to Maintain Cooling Efficiency and Reduce Repair Costs Extend your water pump life withCat Extended Life Coolant.

How do you prime a pump cat water. To prime a water pump start by turning off electrical power to the pump and opening any relief valves on the system. Then insert a hose into the plumbing fixture and turn it. In order to qualify for a core deposit refund the core must meet acceptance criteria.

Typical criteria include but are not limited to. Must be fully assembled and complete not cracked or broken free of excessive rust or pitting free of fire damage and must be. There are other methods to prime a pump which include ancillary pumps vacuum vacuum ejectors andor eductors.

This article only addresses liquid self-priming centrifugal pumps. Sometimes the pump will require manual re-priming after the initial prime. The fluid inside or the initial prime flows through the volute into the discharge cavity.

Here the air and fluid separate the air evacuates through an open ended line or air release line while the fluid returns to the impeller through a recirculation port. Search this section to find the exact part you need for a Cat C7 or C15 Water Pump or another model. We carry the following water pump parts.

How to Maintain Cooling Efficiency and Reduce Repair Costs Extend your water pump life withCat Extended Life Coolant. Its formulated and recommended for Cat engines lasting twice. Flush the pump with a 50 antifreeze 50 water solution before storing.

If conditions are extreme a properly vented enclosure is recommended. This video describes everything needed to change a Cat HEUI pump and what special tooling and techniques are needed to change it. Inspection of the pump is.

How To Prime A Swimming Pool Pump - Very Easy - YouTube. How To Prime A Swimming Pool Pump - Very Easy. It should be electric prime just turn the ignition key on to ignition position before start.

May have to have the safety bar down then you should hear the priming pump on top of the filter whizzing away. Let this run for a minute or so then fire it up. Add water to the filter to prime it so that water will flow once you plug it in.

Water passing through the pump is used to lubricate the seals. Running the pump dry will cause an excessive amount of heat between plungers and the seals causing them to fail in a short amount of time. Never run a pump dry.

Always make sure water is getting to the pump before starting the engine. Inspect and replace all worn seals. Use a priming pump to force out the diesel and air bubbles present in the fuel filter.

Do this process rigorously and repeat it until air bubbles stop coming out. Once it is done close the bleed plug valve. Repeat the same process of priming in all the filters.

If some filters are damaged this is the right time to replace them. How Cat Pumps Work. Cat Pumps are triplex positive displacement reciprocating pumps.

We offer both triplex piston and triplex plunger pump styles. With the positive displacement design each revolution of the crankshaft creates a direct motion in the plungerpiston rods resulting in a positive output of flow from the pump. The primer pump all you do is hand pump it until it becomes firm.

You have removed all the air from the fuel system so the engine will. My recommendation would then be for a 10 micron primary filterwater. Separator element along with the Caterpillar 2 micron secondary fuel.

Filter that you are adding. You will experience less. The primer pump all you do is hand pump it until it becomes firm.

You have removed all the air from the fuel system so the engine will start right up. My recommendation would then be for a 10 micron primary filterwater separator element along with the Caterpillar 2 micron secondary fuel filter that you are adding. You will experience less filter clogs.

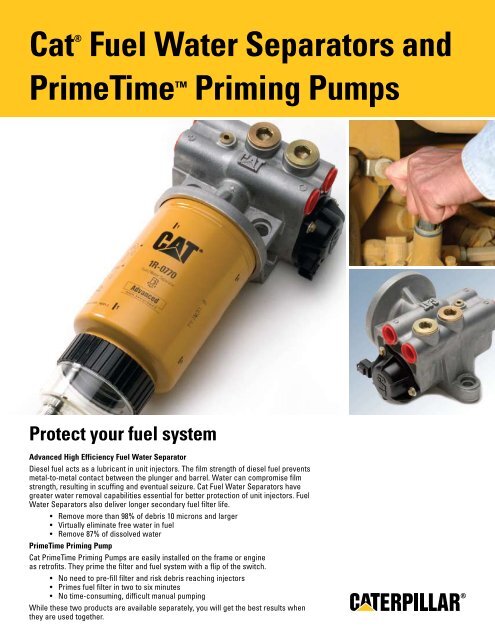

Cat Fuel Water Separators provide the best protection for your critical fuel system. Components by removing large particles virtually all free water and 90 of emulsified. Water to extend the life of your fuel filter and fuel injectors.

Designed and manufactured by Cat we control the quality of the parts you need to keep. Cat Pumps designs and builds products to the highest quality level for one important reason. Our customers depend on our products to keep their equipment running.

Plunger pump performance range is 013 GPM to 240 GPM 049 to 908 LPM and 100 PSI to 10000 PSI 69 BAR to 689 BAR. Pumps are available in brass nickel aluminum bronze 304 316. This is a hollow-shafted pump is designed to bolt directly to a gas engine drive providing easy compact installation.

It has a built-in By-Pass Hose to route the by-pass fluid directly to the pump inlet. The optional Thermo Valve is recommended to protect from overheating during by-pass. At that point it may take only a few seconds of cranking about 5-10 to have that CAT start to fire up.

Unless youre particular CAT equipped coach is different than about 999 of other CAT equipped coaches this is theONLY way of priming the C-7. There is no fuel pump in the tank contrary to what some think. In general you want 12 cm of straight pipe for every centimeter of pump suction diameter.

To maintain laminar flow connect 5-10 pipe diameters of straight piping to the pump inlet. Do not include elbows reducers valves or strainers within the final length of pipework. Connecting an elbow directly to the pump flange for example draws.